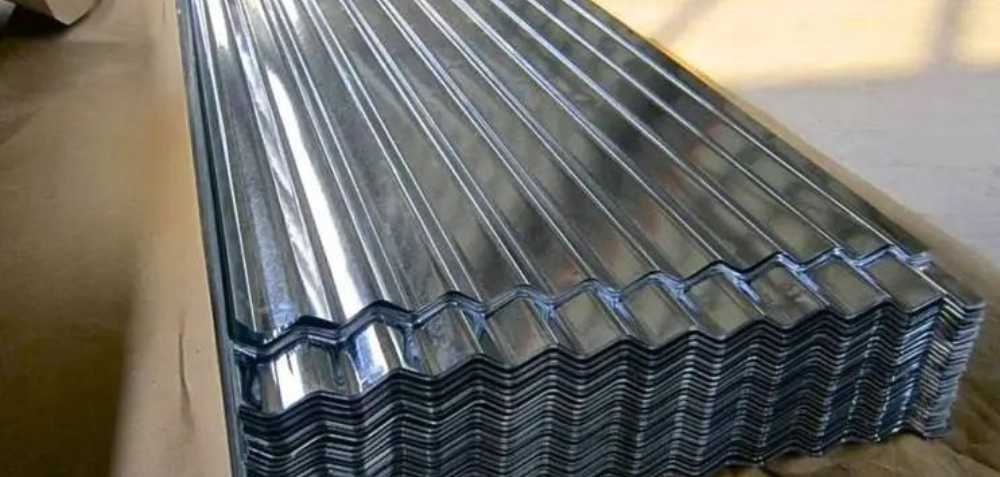

Galvanized Corrugated Sheets

Galvanized Corrugated Sheets

Balaji Build Pro Supplies galvanized corrugated sheet, which is not only high in strength but also lightweight, eco-friendly & durable. Galvanized corrugated sheets are in a linear corrugated pattern. The corrugations increase their strength in the direction which is perpendicular to them. Corrugated sheets are created using Roll forming process. The zinc -iron alloy layers formed during the process of galvanising create a protective coat around the steel and can be subjected to bending and forming without flaking of zinc, keeping moisture out and preventing corrosion.

Balaji Build Pro Suppliers provides top-grade galvanized corrugated sheets, known for their excellent durability and resistance to corrosion. These sheets are ideal for roofing and cladding applications, offering superior protection and longevity. Balaji Build Pro ensures high quality and competitive pricing, making them a trusted choice for galvanized corrugated sheet needs.

Balaji Build Pro Suppliers excels in delivering galvanized corrugated sheets that are meticulously manufactured to meet rigorous industry standards. These sheets provide outstanding durability, weather resistance, and protection against corrosion, making them perfect for both residential and commercial roofing and cladding projects. With a commitment to quality, Balaji Build Pro employs advanced galvanization processes to ensure long-lasting performance and aesthetic appeal. Clients can rely on their prompt delivery services and competitive pricing, which underscores their reputation as a dependable supplier in the market.

The softness in the corrugated sheets is achieved by annealing process in the galvanizing line. GC sheets come in a wide variety of thicknesses from 0.12 mm to 0.60 mm and widths (900 mm/ 1220 mm) to suit your project. Balaji Build Pro is an authorized distributor for GC sheets manufactured by Jindal India.

Technical Specifications

Material: As per ISI Specification IS:277-2003

Weight per piece ( 3.0 Feet - 900 mm)

| Thickness | 6ft | 8ft | 10ft | 12ft | 14ft | 16ft | 18ft | 20ft |

|---|---|---|---|---|---|---|---|---|

| (mm) | 1829 | 2438 | 3048 | 3658 | 4267 | 4877 | 5486 | 6096 |

| 0.12 | 1.722918 | 2.296596 | 2.871216 | 3.445836 | 4.019514 | 4.594134 | 5.167812 | 5.742432 |

| 0.16 | 2.297224 | 3.062128 | 3.828288 | 4.594448 | 5.359352 | 6.125512 | 6.890416 | 7.656576 |

| 0.2 | 2.87153 | 3.82766 | 4.78536 | 5.74306 | 6.69919 | 7.65689 | 8.61302 | 9.57072 |

| 0.25 | 3.5894125 | 4.784575 | 5.9817 | 7.178825 | 8.3739875 | 9.5711125 | 10.766275 | 11.9634 |

| 0.3 | 4.307295 | 5.74149 | 7.17804 | 8.61459 | 10.048785 | 11.485335 | 12.91953 | 14.35608 |

| 0.35 | 5.0251775 | 6.698405 | 8.37438 | 10.050355 | 11.7235825 | 13.3995575 | 15.072785 | 16.74876 |

| 0.4 | 5.74306 | 7.65532 | 9.57072 | 11.48612 | 13.39838 | 15.31378 | 17.22604 | 19.14144 |

| 0.45 | 6.4609425 | 8.612235 | 10.76706 | 12.921885 | 15.0731775 | 17.2280025 | 19.379295 | 21.53412 |

| 0.5 | 7.178825 | 9.56915 | 11.9634 | 14.35765 | 16.747975 | 19.142225 | 21.53255 | 23.9268 |

The weight mentioned is subject to tolerance of + - 10%

Weight per piece ( 4.0 Feet - 1220 mm)

| Thickness | 6ft | 8ft | 10ft | 12ft | 14ft | 16ft | 18ft | 20ft |

|---|---|---|---|---|---|---|---|---|

| (mm) | 1829 | 2438 | 3048 | 3658 | 4267 | 4877 | 5486 | 6096 |

| 0.2 | 3.7904196 | 5.0525112 | 6.3166752 | 7.5808392 | 8.8429308 | 10.1070948 | 11.3691864 | 12.6333504 |

| 0.25 | 4.7380245 | 6.315639 | 7.895844 | 9.476049 | 11.0536635 | 12.6338685 | 14.211483 | 15.791688 |

| 0.3 | 5.6856294 | 7.5787668 | 9.4750128 | 11.3712588 | 13.2643962 | 15.1606422 | 17.0537796 | 18.9500256 |

| 0.35 | 6.6332343 | 8.8418946 | 11.0541816 | 13.2664686 | 15.4751289 | 17.6874159 | 19.8960762 | 22.1083632 |

| 0.4 | 7.5808392 | 10.1050224 | 12.6333504 | 15.1616784 | 17.6858616 | 20.2141896 | 22.7383728 | 25.2667008 |

| 0.45 | 8.5284441 | 11.3681502 | 14.2125192 | 17.0568882 | 19.8965943 | 22.7409633 | 25.5806694 | 28.4250384 |

| 0.5 | 9.476049 | 12.631278 | 15.791688 | 18.952098 | 22.107327 | 25.267737 | 28.422966 | 31.583376 |

The weight mentioned is subject to tolerance of + - 10%